For recycling to happen, packaging waste must first be collected and sent to a mill. Waste arising during manufacture is relatively easy to collect, this is trimmed waste from cartonboard mills and from carton manufacturers. However, the bulk of cartonboard, along with all paper and board products, is spread throughout society and an infrastructure is required for its collection.

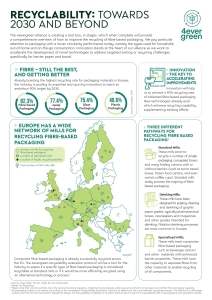

Attaining a high recycling rate depends on achieving a high collection rate! Strict discipline in separating carton packaging after use and delivering it to a recycling site is the first step towards securing a high recycling rate. European consumers understand the importance of collecting and separating valuable cardboard. This has led to a recycling rate of 82% for fibre based packaging (Source: Eurostat 2018). This is significantly higher than any other packaging material. The industry is moving the bar even higher by targeting a recycling rate of 90% by 2030.

More than 60 million tonnes of used paper are collected in Europe each year. The main sources of paper collection are 50% from trade and industry, 40% from households, and 10% from offices. The banning of plastic bags by most retailers in Europe will increase the 40% share of paper collection from households, while industrial sources are already at collection capacity. So it is even more important that we are all very disciplined in separating our fibre based packaging materials and making those high quality fibres available to the respective recycling streams. For the cartonboard and carton industry, recycled fibres are an indispensable source of raw materials, supporting the industry’s resource efficiency.

Fibres of cartonboard materials are a valuable resource for new cartonboard production. The latest research results from TU Graz/Austria conclude that cartonboard fibres can be recycled at least 25 times. Any packaging that consumers send for recycling will have at least 25 lives left after its first use.

Pro Carton speaks to Rene Eckhart, Senior Scientist, TU Graz about the claim that cartonboard can be recycled 25 times (at least)

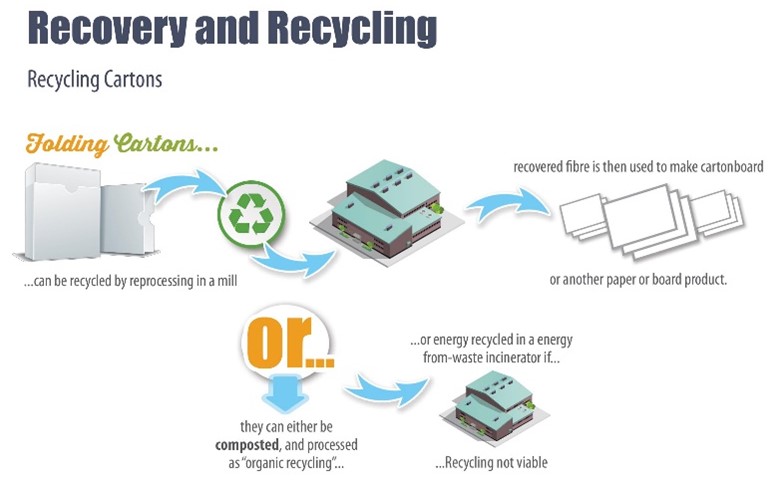

Carton Recycling

Cartons can be recycled by reprocessing in a mill, where the fibres are separated. The recovered fibre is then used to make cartonboard or another paper or board product. Alternatively, cartons can be composted, a process known as “organic recycling”, or ultimately their energy content can be recovered in an energy-from-waste incinerator. The industry target is to maximize the share of used cartons as part of a continuous feed for new cardboard production. Recycled fibres are an indispensable source of raw materials, too good to be composted or incinerated. The biggest value to the global climate is to keep the fibers in the circular system and to produce new cartonboard packaging. Again and again.

Reduction of the volume of landfill waste makes an important contribution to achieving the target of 65% of biodegradable materials that should be recovered by 2030 under the EU Landfill Directive.

The Quality of Recovered Fibre

The quality of fibre that is recovered from cartonboard and cartons depends on a number of factors:

- Are they long or short fibres?

- How were they separated from the original wood?

- Were they bleached?

- To what extent were other materials such as coatings, ink, plastics, wet strength resins and adhesives used?

Fibre quality therefore depends on the initial fibre separation and treatment, how the fibres were made into paper or board and how those products were used.

The quality of recycling paper ranges from virgin pulp substitute grades (unprinted white trimmings), office waste, newsprint, brown (unbleached) packaging to mixed papers and boards. The grade or type of recycling paper and market demand determines the price.

Composting Cartonboard

After the paper based part of the waste stream is collected and the paper and board suitable for recycling is sorted and sent for reprocessing, cartonboard packaging and paper which isn’t suitable for recycling for technical or hygiene reasons can be sent for composting.

The benefits of composting (post consumer) cartonboard packaging include:

- Diversion of used cartonboard packaging from landfill

- Recovery and recycling of packaging material

- Results in a beneficial soil compost

- Provides a sustainable alternative to peat

- Diversion of used cartonboard from mass burn incineration

Composting occurs when organic material is broken down by micro-organisms to produce a mulch which can be used for agriculture or horticulture.

Cartonboard is ideal for composting because wood fibre is biodegradable. This means that it can be broken down into natural substances by bacteria using microbial enzymes, thereby producing carbon dioxide, water and compost (humus).

Compost can be made from raw materials high in carbon, such as cartonboard, combined with a material containing nitrogen. For waste managers and local authorities this could provide an alternative process to recover part of the packaging waste stream.

4evergreen Alliance:

The Pro Carton Fact File is a great educational tool that looks in depth at the cartonboard industry.

Module 7 focusses on Recycling and is downloadable in our Publications area.